How did we proceed?

Developing an integrated project schedule

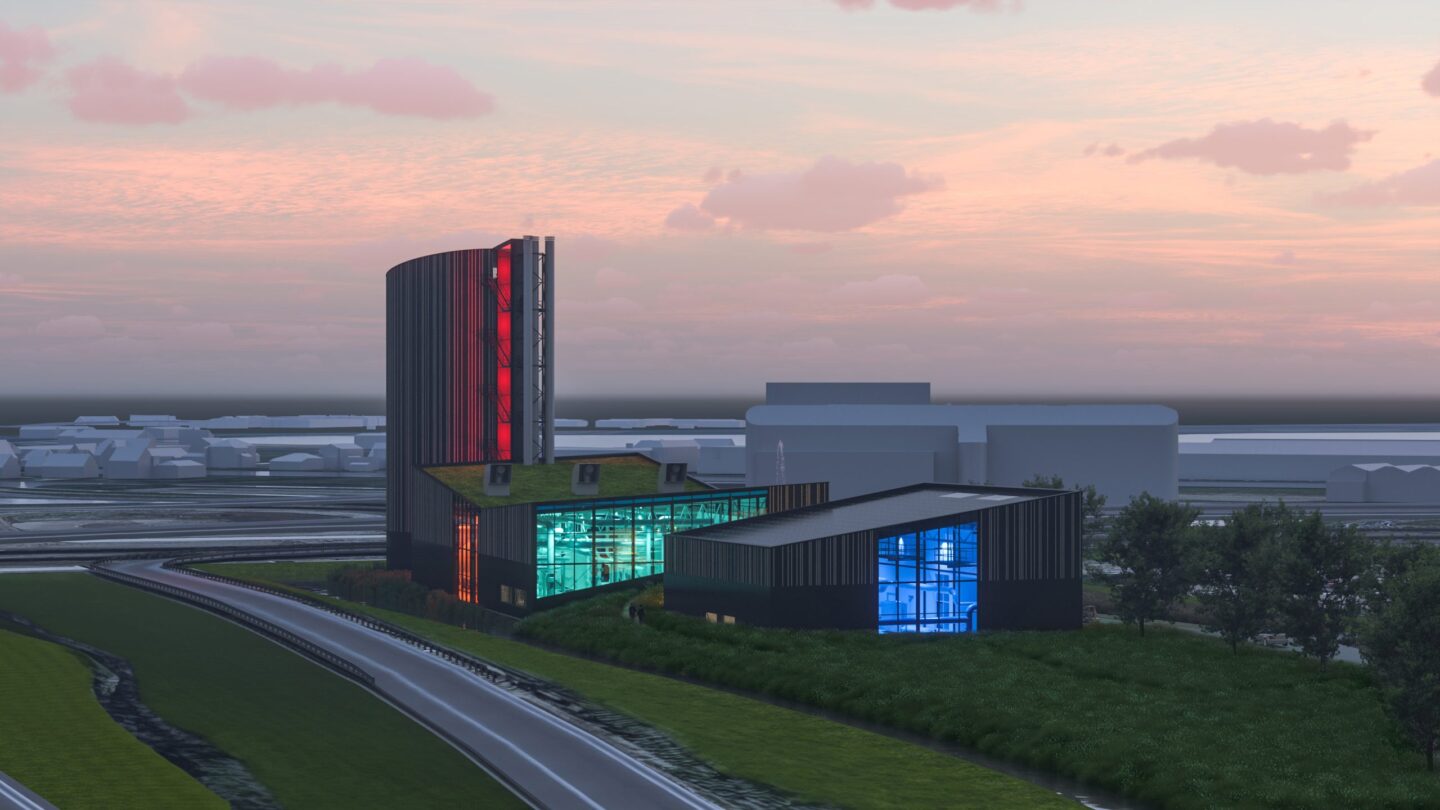

For the construction of “De Sleutel” (The Key), Croonwolter&Dros, as the main contractor, is responsible for coordinating all subcontractors and external parties. Using Primavera P6, I began by setting up an integrated project schedule supported by all internal and external disciplines. This comprehensive schedule provided a realistic timeline, clearly mapping out the project’s feasibility and potential bottlenecks. After mitigating these bottlenecks, a baseline was established in consultation with both the client and the contractor.

Monitoring engineering, procurement, and execution

Based on a clear overall schedule, operational activities are closely monitored. Every two weeks, progress is collected and updated in the plan. This information allowed for detailed analysis of the schedule and any potential shifts, enabling timely mitigation actions. For example, assessing the impact of delays in certain activities and providing tailored advice to minimize these delays.

Creating a 6-week execution schedule

During execution, the need for an integrated 6-week schedule grew: one that combined the sub-schedules of all participating parties. By consolidating various Excel and Microsoft Project schedules into a single 6-week plan within Primavera P6, an execution schedule was developed. This integration optimized the alignment between the 6-week schedule and the overall schedule, ensuring that the combined duration of sub-activities accurately reflected the overarching activity. Through a rolling-window approach, new information is added each week to keep the schedule as up-to-date as possible.